A standard garage circuit or household circuit has a 20-AMP max breaker capacity. Or as close as you can get it 65-in.

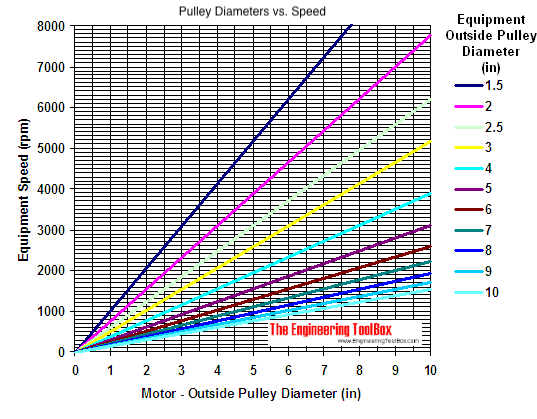

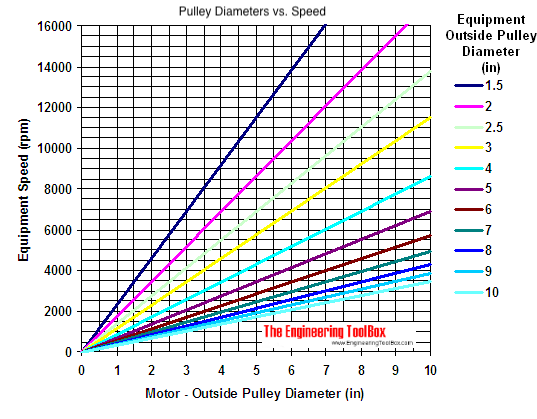

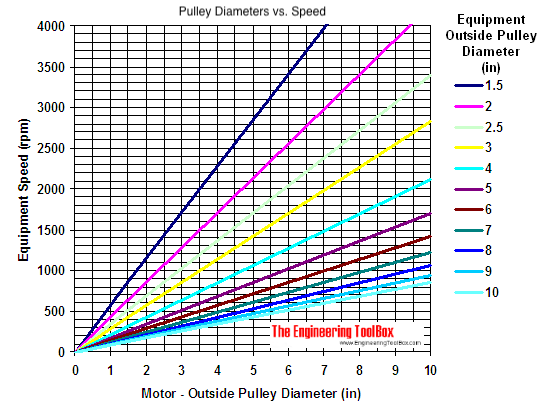

Motors Speed Vs Pulley Diameter

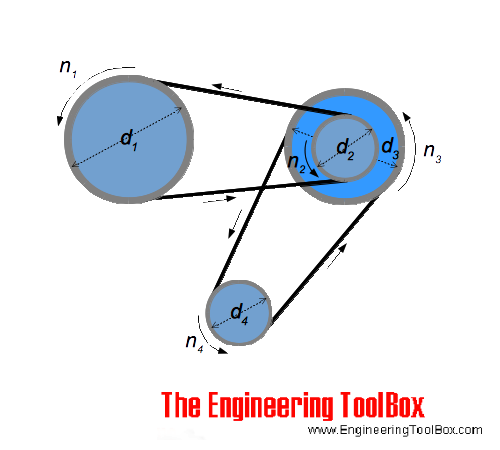

For example if Pulley 1 is 80mm diameter and spins at 1000 RPM and you need to find the Pulley 2 size to spin it at 400 RPM.

. In both cases its ideal to have an unloading valve so the motor is basically starting a free pump. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators. Then take the 436 ratio and divide into the motor rpm 3450rpm.

Nameplate says 230 volts usable 208 volts 65 amps 230 volts SF 115. When a motor operates at 100 of its FLA its operating at 100 of its capacity. 208 volt single phase one hp.

The wire size chart below shows allowable ampacities of insulated conductors rated up to and including 2000 Volts 60C through 90C 140F through 194F not more than three current-carrying conductors in raceway cable or earth directly buried based on ambient air temperature of 30C 86F. Can be calculated as. _ 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 _ 116 18 316 14 516 38 716 12 916 58 1116 34 1316 78 1516.

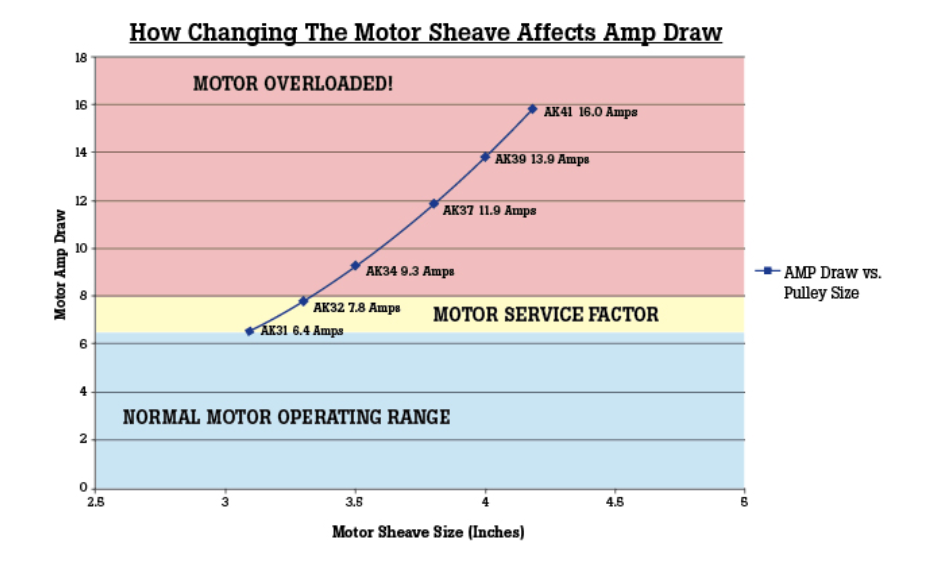

This will also increase load on motor and cause higher Amp draw make sure motor is not overloaded not drawing more Amps than rated for Example. Wire Gauge Chart vs Amps vs Length. With a ratio of 0611 and a 4-inch pulley on your motor you would need a 655-inch pulley on your pump.

Changing a pulley size or making an adjustment on the motor pulley if it is adjustable will accomplish this. I know if I install a larger diameter pulley on the motor it will slow the blower down. February 16 2018 Ryan Electrical.

Use this chart to help determine what size wire you should be using based on AMPS being pulled and the length of the wire you will be running. Pulley or a 3450 rpm motor with a 4 dia. And always use a fuse smaller than the rating of the wire to prevent fires.

The motor is now running continuously at its service factor generating additional heat and shortening the motors useful life. This shows there is more HP available. D4 60 mm.

Of course this will only work if the pulley diameter is at least 65-in. If the drive pulley on the engine is 4 inches in diameter we need to calculate 4315 1270. With the pulley a 4 is about 13 the size of an 8.

Would the hirer rpm with a smaller pulley have more starting torque. Motor and equipment speed for pulleys with different diameters are indicated in the charts below. RPM Belt Length Belt-Surface Speed Animated Diagrams - Metric.

Notice the airflow increased 17 and the pulley size also increased 17. D3 110 mm. When a system has been renovated and system performance has been maximized its common to read amp draw at 80 to 90 of FLA on most direct-drive.

Belt Width mm Face Width mm Bearing centers mm Max. How does pulley size affect amp draw. N4 1000 rpm 100 mm 110 mm 50 mm 60 mm 3667 rpm.

Increasing the pulley to 32 inches also increases the amp draw to 78. You would use the ratio we discovered in our last step 0611 to figure out what size pulley you would need on your pump. Even if you used a 1 HP motor with the 5hp size sheave the load would still demand the same 5HP or 20 amps and force the 1 HP motor to.

D1 100 mm. Pulley RPM and belt length calculator diagram. A 1750 rpm motor with a 8dia.

4 inches 0611 655 inches. The revolutions of shaft 4 in a multiple belt transmission like indicated in the figure above where. If using a 17501800 motor then.

Allowable shaft ø mm Bearing Center Type. Pulley adjustments can be hazardous to the health of your motor. This means that the pump pulley must be 1270 inches in diameter to run the pump at 1070 rpm.

How does pulley size affect motor amps. You then multiply the drive pulley diameter x 12 to get 72 or about 7 316 to get to that RPM. Wire Size Chart and Maximum Amp Ratings.

07-31-2011 1156 AM 14. With the original 31-inch pulley the motor draws 64 amps which is within its operating range. The goal of the test Ill present here is to compare the measured amps that the motor is using to the FLA capacity of the motor.

Remember when in doubt bigger is always better. May 1 2013. N1 1000 rpm.

Duct work On hot air furnaces would have different back pressure so I would adjust pulley to the motor specs using a Amp probe. Increasing the pulley sizes to 345 or 355 will leave the motor continually operating in an overloaded mode. Yes larger motor pulley will increase fan RPM.

Use non detergent 30wt sae compressor oil. My true 5hp compressor motor is rated at 23amps so yours is probably not a true 7 hp that is probably peak hp. Increasing the pulley to 32 inches also increases the amp draw to 78.

The motor is now running continuously at its service factor generating additional heat and shortening the motors useful life. Size and divide. The rpm of the pump needs to be between 600 900 rpm.

If you know any 3 values Pulley sizes or RPM and need to calculate the 4th enter the 3 known values and hit Calculate to find the missing value. D2 50 mm. Dec 3 2014 4 F FlashKat.

Also the fan and motor capacity must be at least 6000 CFM. You need to figure the circumference not the diameter and I am lousy at math. In practice adjusting a sheave to get a belt to ride lower closer to the shaft or higher further from the shaft wont usually result in huge airflow changes but it.

Motor is running 74 amps and I have the belts adjusted on the loose side. Motors Pulley Diameters And Speed What we all can do with the MagneTrainer that cannot be done with any exercise bike is push the unit away using as a recumbent draw in closer sitting in a higher chair using it as a traditional bike and use it for arm strength. 1 in 254 mm.

To figure out what size pulley you need take the flywheel od. What will that. You can view a technical page from our catalog here it will help to further explain the calculation process.

Adjust the motor pulley to 644-in. The motor can do more work. D1 100 mm.

I just installed an exhaust blower motor. Broken down into a math problem this looks like. The most economical and practical pulley to replace is the motor pulley.

For this motor if it is doing a full 10 HP work load it would draw 235 amps it is only drawing 16 amps. If it is doing a full 10 HP work load it would draw 235 amps it is only drawing 16 amps. Will do to take the airflow up to 6000 CFM.

This will give you the compressor rpm 345043679128 rpm.

Is Changing Fan Pulleys A Cost Effective Shortcut To Boost Fan Output The Poultry Site

Correctly Sizing A Pump Pulley Sheave All Applications All Pumps

Belts Pulley Diameters Vs Speed

Motors Speed Vs Pulley Diameter

Motors Speed Vs Pulley Diameter

9 Free Band Saw Plans Build Your Own Band Saw Or Saw Mill Bandsaw Woodshop Tools Diy Bandsaw

0 comments

Post a Comment